The CF-ERP system is CFC independent research and development, which can meet the demands of production and management. CFC has cooperated with the China telecom and mobile and leased their Cloud database and SMS platform to store various kinds of information, and also built CFC Cloud together with our company self-built "private clouds". CFC Cloud can show the safety operation standard (SOP), remote monitoring videos of the whole plant, 2D scanning data (QR code), real-time monitoring data of products, online monitoring data of mechanical equipment, safety education videos, operating procedure of the quality standard (ISO-9001), company profile videos, operating procedure of manufacturing standard, operating videos of manufacturing standard, history data of product maintenance and so on. It realizes the transformation of flat face to stereo face and the partial to the overall overview, and effectively broadens the space and time limit of management.

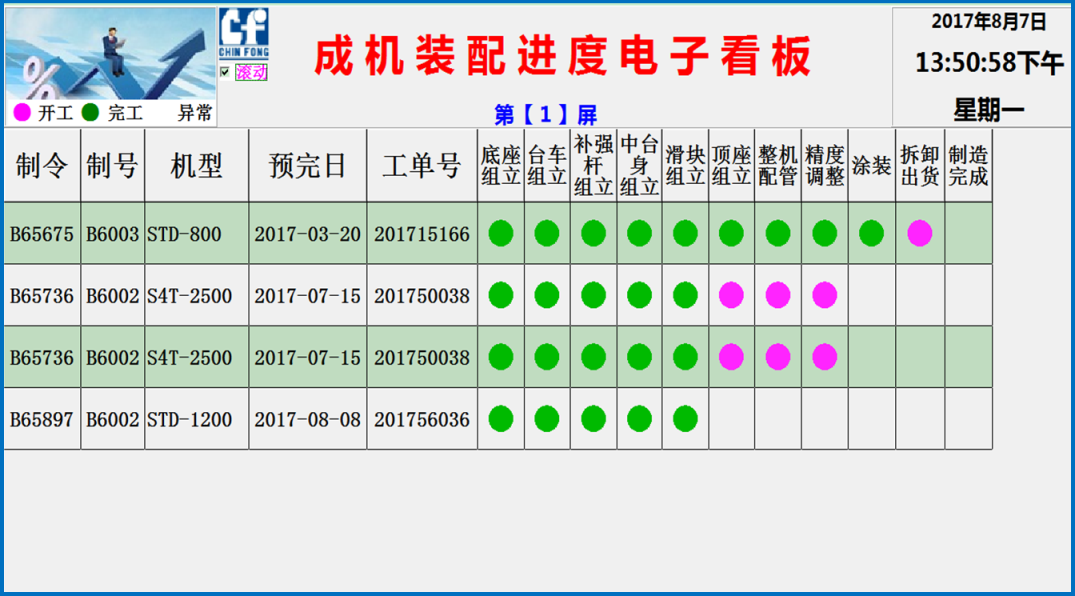

We can collect the working hours of workers at the production lines by barcode technology on the workstations, realize the electronic bulletin of assembly progress of finished products, and accurately meet the demands of customer`s delivery.

All processing equipments have installed the Current Sensor, which can send the operation condition to the Cloud database, then automatic send the current status back to the indicator lamp after the analysis of big data to remind the operators and reduce the invalid operation condition. CFC factory is divided into twelve regions according to the using features, and each region is equipped with smart meters, which can upload the the condition of electric consumption to the Cloud at any time. We can achieve the seasonal trend analysis of the electric consumption of different departments, electric consumption management of the peak and valley period, the electric consumption of MBO, cost accounting and management, intelligent switch and so on. Our purpose is energy saving and green production.

Each of CFC equipment installed all kinds of Sensors to monitor the operation frequency, current, temperature, pressure and equipment failure code, and so on. The data can not only provide customers with the online monitoring of production status, but also can search the running status through the text message. Meanwhile, it also can provide customers with the maintenance information when the production data combine with the MIS system of customers. Our concept is whole life cycle of product service, and we believe that the good service is the beginning of the next sales. So we provide customers with the informationalized and fast service system, which can do real-time monitoring to the products, can warn before issues happening, provide customer with message warning of the maintenance, and do remote maintenance for the press, etc. Above of all improve the operation reliability and safety.

We also can use GPS system to find the nearest service vehicle and dispatch it to the customers` factory for maintenance in real time, so as to ensure the effective operation of the equipment. After maintenance, the service staff will directly scan the equipment code (OQ code) by mobile, and input the information into the CFC Cloud, such as the failure reason, the time of replacing parts, and so on. So whether our service staff or the customers can browse the equipment maintenance record at any time, so as to provide a lot of support to the customer production equipment.